Reflux Valve

Reflux Valve Specification

- Connection Type

- Flanged Ends

- Control System

- Manual

- Valve Size

- 2 inch (50 mm)

- Material

- Cast Iron Body

- Sealing

- Nitrile Rubber/EPDM

- Application

- Industrial fluid handling, chemical processing, water systems

- Structure

- Single plate, unibody construction

- Voltage

- Not required

- Media

- Water, Oil, Gas

- Port Size

- 2 inch (50 mm)

- Disc

- Stainless Steel

Reflux Valve Trade Information

- Minimum Order Quantity

- 1 , , Piece

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 10 Pieces Per Day

- Delivery Time

- 15 Days

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Reflux Valve

Our company has been expanding rapidly and become a well known manufacturer, exporter and supplier of qualitative Reflux Valve. The offered dimensionally accurate valve is widely used for fitting and fixing purpose in hydraulic and pneumatic machines. Under experts' proper guidance, this valve is manufactured with the help of ultra-modern machines by utilizing superior quality raw materials. Further, our customers can avail this Reflux Valve from us in several specifications at economical prices.

Features:

-

Accurate dimension

-

Easy to install

-

Withstand high pressure

Other Info:

-

Bolted Cover, Swing Type

-

Flange Dimension as per IS : 1538

-

Alternative Flanges can be provided.

| Body | Cast Iron IS : 210 Gr. FG - 200 |

| Cover | |

| Disc | |

| Hinge | |

| Seat Ring | Gun Metal Or Stainless Steel CF - 8 / CF - 8M |

| Disc Ring | |

| Hinge Pin | Stainless Steel AISI - 410 |

| Gasket | Rubber / C. A. F. |

| Bolt & Nut | Carbon Steel |

| Hydrostatic Test Pressure in Kg/Cm2 (PSI) | ||

| Class | Shell | Seat |

| 50mm to 125mm | 24 (342) | 16 (228) |

| 150mm to 300mm | 15 (213) | 10 (142) |

| 350mm to 600mm | 9 (128) | 6 (85) |

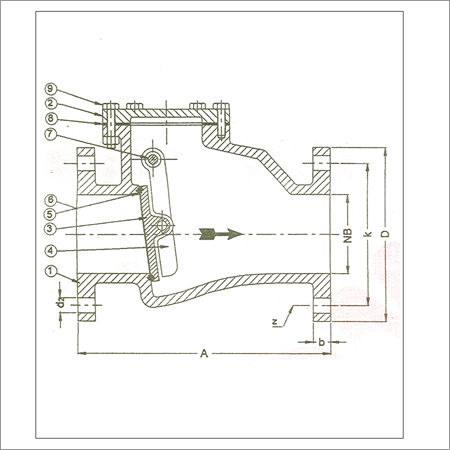

Dimensions Are In MM

| Mark | Size | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 |

| A | 200 | 230 | 260 | 300 | 350 | 400 | 500 | 600 | 700 | 800 | 900 | 1000 | 1100 | 1300 | |

| IS : 1538 | D b k d2 z | 165 | 185 | 200 | 220 | 250 | 285 | 340 | 395 | 445 | 505 | 565 | 615 | 670 | 780 |

| 16 | 16 | 21 | 22 | 22 | 23 | 25 | 26 | 28 | 29 | 30 | 32 | 33 | 36 | ||

| 125 | 145 | 160 | 180 | 210 | 240 | 295 | 350 | 400 | 460 | 515 | 565 | 620 | 725 | ||

| 18 | 19 | 19 | 19 | 19 | 23 | 23 | 123 | 23 | 23 | 28 | 28 | 28 | 31 | ||

| 4 | 4 | 4 | 8 | 8 | 8 | 8 | 12 | 12 | 16 | 16 | 20 | 20 | 20 |

- Outside lever & Counter Weight can be provided.

- Dashpot arrangement can be provided.

- By Pass / Drainage system can be provided.

- Air Release Plug can be provided.

Robust Construction and Quality Material

The Reflux Valve utilizes a single plate, unibody design for strength and longevity. With a cast iron body and stainless steel disc, it ensures corrosion resistance and durability in demanding environments. Seals made from Nitrile Rubber or EPDM help maintain high performance and prevent leaks even during fluctuating pressures.

Versatile Application Across Industries

Ideal for industrial fluid handling, chemical processing, and water systems, this valve suits a wide range of media including water, oil, and gas. Flanged ends ensure straightforward integration into existing pipelines while manual operation provides simple, reliable control. Its 2-inch size meets common industry standards, guaranteeing compatibility and convenience.

FAQs of Reflux Valve:

Q: How is the Reflux Valve installed in industrial fluid handling systems?

A: The Reflux Valve features flanged ends for secure and straightforward installation into pipelines. It is manually operated, making it easy to control flow without requiring electrical power or complex systems.Q: What are the benefits of using a single plate, unibody Reflux Valve?

A: A single plate, unibody construction minimizes potential leak points and offers enhanced durability, ensuring consistent performance in rigorous industrial environments.Q: When should the valves sealing be checked or replaced?

A: Routine inspections are recommended, especially if the valve operates in high-pressure or chemically aggressive conditions. Quality Nitrile Rubber or EPDM seals typically offer long service life, but should be replaced upon signs of wear or leakage.Q: Where is this valve commonly used within industrial settings?

A: This valve is typically installed in water treatment plants, chemical processing pipelines, and industrial fluid handling systems where reliable backflow prevention is essential.Q: What process does the valve follow to prevent backflow in the system?

A: The stainless steel disc inside the valve automatically closes when reverse flow is detected, sealing tightly against the Nitrile Rubber or EPDM seat to prevent backflow and protect system integrity.Q: How does manual control enhance usage of this Reflux Valve?

A: Manual control allows operators to quickly adjust or isolate the valve as needed, providing precise management without relying on external power sources.Q: What advantages does a cast iron body offer for valve performance?

A: Cast iron is known for its strength and resistance to corrosion, which significantly extends the valves operational lifespan and reliability in challenging industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

|

FLOMECH VALVES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry