Industrial Swing Check Valve

Industrial Swing Check Valve Specification

- Material

- Cast Iron / WCB / Stainless Steel

- Valve Type

- Check Valve

- Control System

- Manual

- Connection Type

- Flanged Ends

- Valve Size

- Available from 1 to 12

- Sealing

- EPDM / NBR / PTFE seat

- Application

- Industrial fluid, gas, and steam pipeline systems

- Structure

- Swing Type

- Type

- Swing Check Valve

- Pressure

- Class 150 / PN16 (16 bar)

- Media

- Water, Air, Oil, Gas, Steam

- Port Size

- DN25 to DN300 (1 to 12)

- Disc

- Bronze / Stainless Steel

- Pin

- Stainless Steel Hinge Pin

Industrial Swing Check Valve Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10 Pieces Per Day

- Delivery Time

- 15 Days

About Industrial Swing Check Valve

Industrial Swing Check Valve

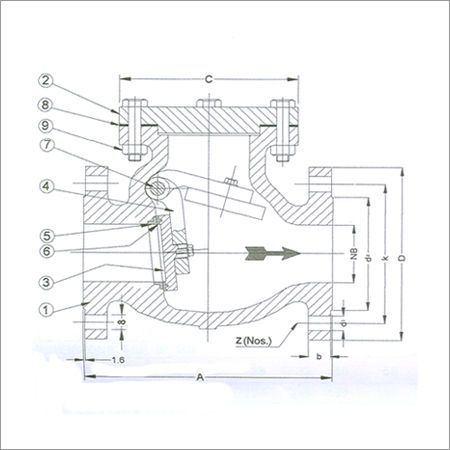

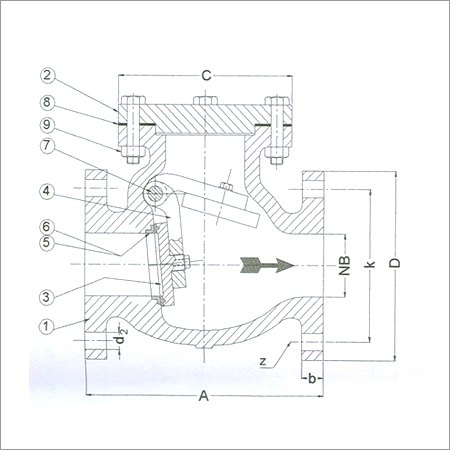

Manufacturing Standard: BS: 5153, Class-125

Bolted Cover, Swing Type

- Face to face dimensions as per ANSI B16.10

- Flange dimension as per ANSI B16.5

Alternative Flanges can be provided

Nomenclature and Materials:

| 1. | Body | Cast Iron IS:210 Gr. FG-200 |

| 2. | Cover | |

| 3. | Disc | |

| 4. | Hinge | |

| 5. | Seat Ring | Gun Metal or Stainless Steel CF-8/CF-8M |

| 6. | Disc Ring | |

| 7. | Hinge Pin | Stainless Steel AISI-410/304 |

| 8. | Gasket | Rubber/C.A.F/Spiral Wound |

| 9. | Bolts & Nuts | Carbon Steel |

| Hydrostatic Test Pressures in Kg/Cm2 (PSI) | ||

| Class | Sheel | Seat |

| 125 | 24 (342) | 16 (228) |

Dimensions are in mm

| Mark | Size | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 |

| ANSI B 16.1 Class-125

| A | 203 | 216 | 241 | 292 | 333 | 356 | 495 | 622 | 699 | 787 | 864 | 978 | 978 | 1295 |

| C | 130 | 210 | 248 | 285 | 305 | 394 | 483 | 533 | 591 | 667 | 691 | 733 | 775 | 911 | |

| D | 152 | 178 | 191 | 229 | 254 | 279 | 343 | 406 | 483 | 533 | 597 | 635 | 699 | 813 | |

| b | 19 | 22 | 24 | 24 | 24 | 25 | 29 | 30 | 32 | 35 | 37 | 40 | 43 | 48 | |

| k | 121 | 140 | 152 | 191 | 216 | 241 | 298 | 362 | 432 | 476 | 540 | 578 | 635 | 749 | |

| d2 | 19 | 19 | 19 | 19 | 22 | 22 | 22 | 25 | 25 | 29 | 29 | 32 | 32 | 35 | |

| z | 4 | 4 | 4 | 8 | 8 | 8 | 8 | 12 | 12 | 12 | 16 | 16 | 20 | 20 |

- Testing as per API 598/BS:5146

- Outside lever & weight type can be provided

- By Pass/Drainage System can be provided

Reliable Performance Across Media

Designed to handle a range of media like water, oil, gas, air, and steam, the swing check valves precision sealing and durable build ensure minimal leakage and sustained reliability. Its versatility suits various industrial applications, offering peace of mind by preventing reverse flow in critical pipeline systems.

Flexible Sizing and Robust Build

Available in sizes from DN25 to DN300 (1 to 12), these valves offer flexibility for diverse installations. Made from quality materials such as cast iron, WCB, or stainless steel and featuring durable bronze or stainless steel discs, the valve provides long-term service with resistance to wear and corrosion.

Application Versatility

Suitable for fluid, gas, and steam pipelines, these swing check valves adapt to multiple control requirements. Their manual operation, coupled with flanged ends for straightforward connection, streamline installation and maintenance processes in industrial environments.

FAQs of Industrial Swing Check Valve:

Q: How does an industrial swing check valve prevent backflow?

A: An industrial swing check valve uses a hinged disc that swings open in the direction of flow and automatically closes when flow reverses, effectively preventing backflow and protecting equipment within the system.Q: What media can be handled by this swing check valve?

A: This valve is suitable for water, air, oil, gas, and steam, making it highly versatile for use in various industrial pipeline applications.Q: When should I choose an EPDM, NBR, or PTFE seat for the valve?

A: Select EPDM for water and mild chemicals, NBR for oils and hydrocarbons, and PTFE for handling aggressive chemicals or high-temperature steam. Choice depends on the type of media and operating conditions.Q: Where can this valve be installed within an industrial system?

A: The swing check valve can be installed in any segment of a fluid, gas, or steam pipeline where preventing reverse flow is required. Common locations include upstream of pumps or sensitive equipment.Q: What is the process for installing this valve?

A: Installation involves aligning the flanged ends with the pipeline, ensuring correct flow direction, and securing the connections per manufacturer guidelines. Proper installation ensures optimal performance and safety.Q: What are the benefits of using a swing check valve with a stainless steel hinge pin and disc?

A: A stainless steel hinge pin and disc enhance the valves strength and resilience, providing superior corrosion resistance and longer service life, especially in demanding or corrosive environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Swing Check Valve Category

Lined Swing Check Valve

Price Range 700.00 - 7000.00 INR / Piece

Minimum Order Quantity : 1 , , Piece

Type : Lined Swing Check Valve

Connection Type : Flanged Ends, ANSI B16.5 / DIN Standards

Valve Size : 1 to 12 (DN25 to DN300)

Pin : Stainless Steel

|

FLOMECH VALVES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry