Diaphragm Valve Straight

Diaphragm Valve Straight Specification

- Application

- Chemical Processing, Water Treatment, Pharmaceuticals, Food and Beverage

- Size

- Standard sizes from 15 mm to 150 mm

- Color

- Black / Blue / Metallic (subject to material)

- Pressure

- Up to 10 Bar (varies by model and material)

- Connection

- Flanged / Threaded / Socket Weld

- Type

- Diaphragm Valve Straight

- Material

- Cast Iron / Stainless Steel / Plastic (as available)

- Temperature

- Up to 120C (depending on material)

- Media

- Water, Air, Steam, Chemical, and Corrosive Fluids

- Standard

- DIN / ANSI / BS (as per manufacturer specification)

- Power

- Manual (Handwheel Operated)

- Port Size

- 1/2 Inch to 6 Inch

- Model

- As per manufacturer catalogue

Diaphragm Valve Straight Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10 Pieces Per Day

- Delivery Time

- 15 Days

About Diaphragm Valve Straight

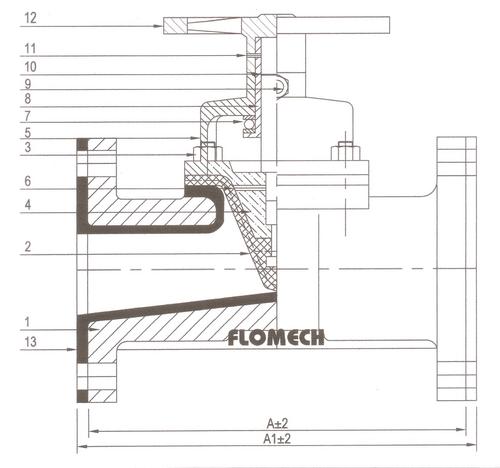

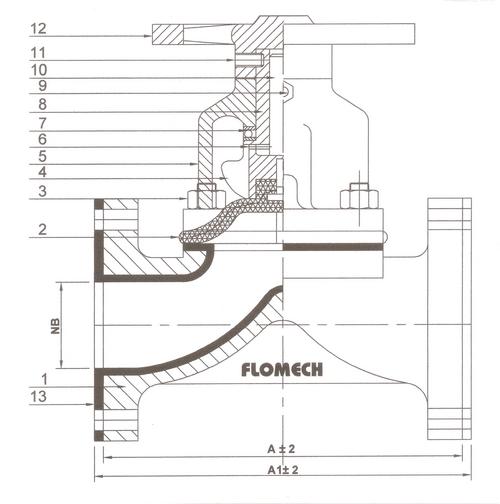

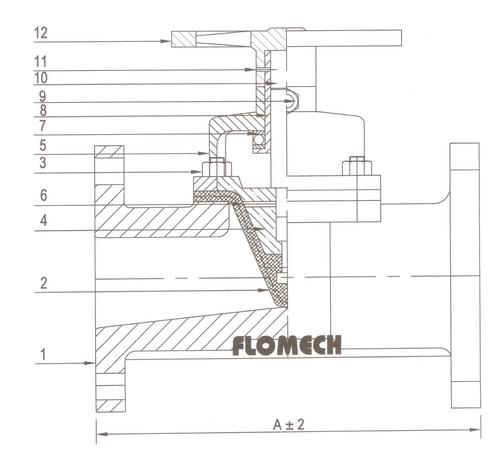

Diaphragm Valve Straight Through Type

- Straight through type, Non-rising Spindle, Bolted Bonnet.

- Flange Dimension as per BS : 10, Table-D / ANSI B16.5 Class - 125 Flat Faced.

| Body | Cast Iron / Cast Carbon Steel / Stainless Steel CF - 8 / CF - 8M |

| Bonnet | |

| Compressor | |

| Hand wheel | |

| Spindle | S.S. AISI -410 |

| Spindle Bush | Mild Steel |

| Compressor PIN | Carbon Steel |

| Diaphragm | Natural / Neoprene / Butyl / PTFE |

| Bolts & Nuts | Carbon Steel |

| Grub Screw | Carbon Steel |

| Grease Nipple | Carbon Steel |

| Thrust Bearing | Carbon Steel |

| Lining | Rubber / Fibre / Glass |

| Hydrostatic Test Pressure in Kg/Cm2 (PSI) | ||

| Size | Shell | Seat |

| 15mm to 150mm | 14 (200) | 10.5 (150) |

| 200mm to 300mm | 10.5 (150) | 7 (100) |

Dimensions Are In MM

| Mark | Size | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 |

| (BS : 5156) (DIN 3202 F1) | A | 108 | 117 | 127 | 146 | 159 | 190 | 216 | 254 | 305 | 356 | 406 | 521 | 635 | 749 |

| A | 130 | 150 | 160 | 180 | 200 | 230 | 290 | 310 | 350 | 400 | 480 | 600 | 730 | 850 | |

| C | 70 | 75 | 93 | 115 | 115 | 130 | 165 | 200 | 240 | 305 | 320 | 455 | 570 | 670 | |

| t | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 4 | 4 | 5 | 5 | 5 | |

| BS : 10 Table - 'D' | D | 95 | 102 | 114 | 121 | 133 | 152 | 165 | 184 | 216 | 254 | 279 | 337 | 406 | 457 |

| b | 10 | 10 | 10 | 13 | 13 | 14 | 14 | 14 | 17 | 17 | 17 | 19 | 22 | 25 | |

| k | 67 | 73 | 83 | 87 | 98 | 114 | 127 | 146 | 178 | 210 | 235 | 292 | 356 | 406 | |

| d2 | 14 | 14 | 14 | 14 | 14 | 17 | 17 | 17 | 17 | 17 | 22 | 22 | 22 | 25 | |

| z | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 8 | 8 | 8 | 8 | 12 | 12 | |

| ANSI B 16.5 Class - 125 | D | 89 | 98 | 108 | 117 | 127 | 152 | 178 | 191 | 229 | 254 | 279 | 343 | 406 | 483 |

| b | 11 | 13 | 14 | 16 | 17 | 19 | 22 | 24 | 24 | 24 | 25 | 29 | 30 | 32 | |

| k | 60 | 70 | 79 | 89 | 98 | 121 | 140 | 152 | 191 | 216 | 241 | 298 | 362 | 432 | |

| d2 | 16 | 16 | 16 | 16 | 16 | 19 | 19 | 19 | 19 | 22 | 22 | 22 | 25 | 25 | |

| z | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 8 | 8 | 8 | 8 | 12 | 12 |

- Screwed End Valves upto 80 mm available.

- Valves body Lining with -

- Rubber (Natural, Neoprene, Ebonite, Butyl, Hypalone),

- LEAD,

- Fiber Glass (Isothelic & Besmothal)

- Face to Face (A) will be higher on lined valves, double of the lining thickness.

- Rubber lining & Fibre Glass thickness 3 mm (upto 150mm) and 5mm (200mm to 350mm)

- Arrangement can be provided with the valve.

- Rising Spindle with Travel Stop,

- Chain Wheel,

- Non-rising Stem with indicating bonnet.

- Thrust Bearing arrangement on 150mm and above sizes.

Versatile Material and Connection Options

Choose from robust body constructions (Glass Lined, PP Lined, Stainless Steel, Cast Iron, and Plastic), and diaphragms tailored for diverse applications. The valve is available in a range of end connections including screwed, flanged, butt weld, and socket weld, allowing easy integration into new or existing piping systems.

Reliable Performance in Demanding Environments

Designed to deliver consistent and safe operation when dealing with water, chemicals, or steam, our diaphragm valves are soft-seated for superior sealing and longer service life. They function efficiently under pressures up to 10 Bar and temperatures reaching 120C (depending on materials), making them suitable for a wide scope of industrial uses.

Ease of Operation and Compliance

Valves are standardly operated manually via handwheel, with options for pneumatic or electric actuation. They feature a full bore to minimize flow resistance, ensuring low pressure drop. All valves meet relevant industrial and sanitary standards, supporting both horizontal and vertical installations for maximum convenience.

FAQs of Diaphragm Valve Straight:

Q: How do I select the appropriate diaphragm and body material for my application?

A: Selection depends on the media and operating conditions. For corrosive chemicals, glass lined or PP lined body with PTFE or EPDM diaphragm is recommended. For water and air, EPDM or Nitrile diaphragms work well. Consult the manufacturers specification to match the valve to your process requirements.Q: What are the main benefits of using a Diaphragm Valve Straight in my system?

A: Diaphragm Valve Straight offers reliable sealing, full bore flow for minimal pressure drop, and excellent resistance to aggressive media. Its design supports frequent operation and long service life, making it ideal in sanitary and industrial processes like water treatment and chemical processing.Q: Where can these diaphragm valves be installed within a piping setup?

A: These valves can be installed in both horizontal and vertical piping arrangements. Their adaptable design and range of end connections ensure compatibility with various system configurations common in industrial facilities.Q: What is the process for maintaining or replacing the diaphragm in these valves?

A: Maintenance typically involves isolating the valve from the system, removing the actuator or handwheel, accessing the diaphragm chamber, and then replacing the diaphragm with a suitable spare. Routine checks ensure optimal performance and longevity.Q: When should I consider manual versus automated actuation for these valves?

A: Manual actuation via handwheel is standard and suited for applications where frequent adjustment is not required. For processes needing remote or automated control, pneumatic or electric actuators can be requested as an upgrade.Q: What standards do these diaphragm valves comply with?

A: The valves meet major international standards such as DIN, ANSI, and BS, depending on the manufacturer specification. This ensures compatibility and safety across a wide range of industrial sectors.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Diaphragm Valves Category

Industrial Diaphragm Valves

Price Range 700.00 - 7000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Application : Industrial Pipeline Systems, Chemical Processing, Water Treatment

Standard : DIN / BS / ANSI

Model : IDV Series

Material : Other , Cast Iron / Stainless Steel / PVC

Rubber Lined Diaphragm Valve

Price Range 700.00 - 7000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Application : Chemical, Water Treatment, Mining, Process Industries

Standard : DIN/BS/ANSI Standard

Model : Rubber Lined Diaphragm Valve

Material : Other , Body: Cast Iron/ Ductile Iron; Liner: Rubber

Metal Diaphragm Valve

Price Range 700.00 - 7000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Application : Chemical Industry, Water Treatment, Pharmaceutical, Food Processing

Standard : ANSI, DIN, BS

Model : Standard Industrial Valve

Material : Other , Metal (Bonnet: Cast Iron, Body: Cast Iron or Stainless Steel)

Diaphragm Valve Weir Type

Price Range 700.00 - 7000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Application : Chemical Industry, Water Treatment, Food & Beverage, Pharmaceuticals

Standard : DIN / ANSI / BS

Model : Weir Type

Material : Other , Cast Iron / Ductile Iron / Stainless Steel / PVC / PP

|

FLOMECH VALVES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry