Lined Swing Check Valve

Lined Swing Check Valve Specification

- Connection Type

- Flanged Ends, ANSI B16.5 / DIN Standards

- Material

- Ductile Iron/Carbon Steel body with PTFE/FEP/PFA Lining

- Valve Size

- 1 to 12 (DN25 to DN300)

- Structure

- Swing Check

- Sealing

- PTFE/Rubber Lined

- Application

- Industrial Fluid Handling, Corrosive Chemical Processes, Water Treatment Plants

- Voltage

- Not Required

- Type

- Lined Swing Check Valve

- Power

- Manual

- Pressure

- PN10 / PN16

- Media

- Acids, Alkalis, Water, Gases

- Port Size

- DN25 to DN300

- Temperature

- Up to 180C

- Disc

- PTFE Lined / Metal Encapsulated

- Pin

- Stainless Steel

Lined Swing Check Valve Trade Information

- Minimum Order Quantity

- 1 , , Piece

- Supply Ability

- 10 Pieces Per Day

- Delivery Time

- 15 Days

About Lined Swing Check Valve

Lined Swing Check Valve

Relying on our state-of-the-art manufacturing set up and diligent professionals, we are manufacturing, exporting and supplying an optimum quality Lined Swing Check Valve. This valve is manufactured using quality raw materials in our sophisticated production unit to ensure. Withstand high pressure, the offered valve is highly demanded in several industries such as petrochemical, marine, oil and gas, pharmaceutical, and many others. In addition, our honorable customers can avail this Lined Swing Check Valve from us at negotiable prices.

Features:

-

Dimensional accuracy

-

Sturdiness

-

Rust proof

-

Easy installation

Other Info:

-

Bolted Bonnet, Swivel Type

-

Face to Face dimensions according to as per ANSI B16.10

-

Flange Dimension as per ANSI B16.5

-

Alternative Flanges can be provided.

| Body | Cast Steel ASTM A216 Gr. WCB Stainless Steel ASTM A351 CF - 8/8M |

| Cover | |

| Disc | |

| Hinge | |

| Seat Ring | Stainless Steel CA - 15/CF - 8 / 8M |

| Disc Ring | 13% CR. Deposited |

| Hinge Pin | Stainless Steel AISI - 410 / 304 |

| Gasket | Sprila Wound |

| Bolts & Nuts | Carbon Steel / SS - 304 |

| Hydrostatic Test Pressure in Kg/Cm2 (PSI) | ||

| Class | Shell | Seat |

| 150 | 30 (425) | 20 (285) |

| 300 | 77 (1100) | 51 (730) |

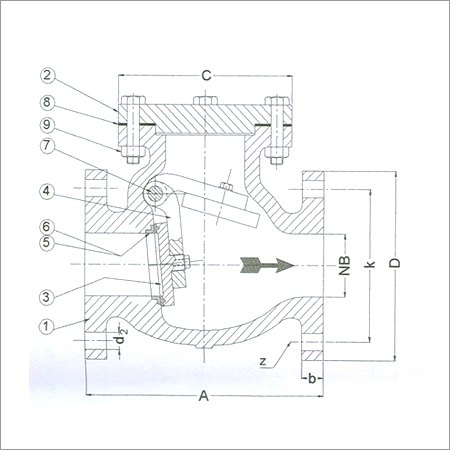

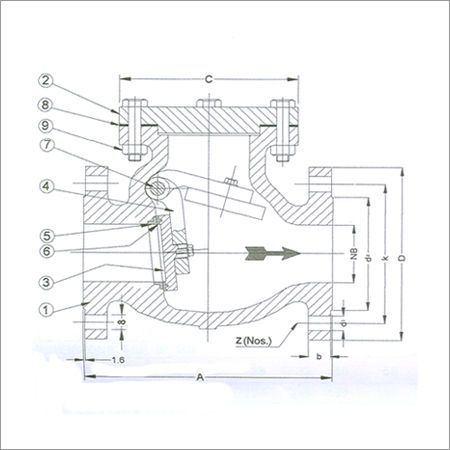

Dimensions Are In MM

| Mark | Size | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 |

| Class-150 Class-300 | A A | 203 | 216 | 241 | 292 | 333 | 356 | 495 | 622 | 699 | 787 | 864 | 978 | 978 | 1295 |

| 267 | 292 | 318 | 356 | 400 | 445 | 533 | 622 | 711 | 838 | 864 | 978 | 1016 | 1346 | ||

| ANSI 16.5 Class-150 | C D b k d4 d2 z | 130 | 210 | 248 | 285 | 405 | 394 | 483 | 533 | 591 | 667 | 691 | 733 | 775 | 911 |

| 152 | 178 | 191 | 229 | 254 | 279 | 343 | 406 | 483 | 533 | 597 | 635 | 699 | 813 | ||

| 19 | 22 | 24 | 24 | 24 | 25 | 29 | 30 | 32 | 35 | 37 | 40 | 43 | 48 | ||

| 121 | 140 | 152 | 2191 | 216 | 241 | 298 | 362 | 432 | 476 | 540 | 578 | 635 | 749 | ||

| 92 | 105 | 127 | 157 | 186 | 216 | 270 | 324 | 381 | 413 | 470 | 584 | 584 | 692 | ||

| 19 | 19 | 19 | 19 | 22 | 22 | 22 | 25 | 25 | 29 | 29 | 32 | 32 | 35 | ||

| 4 | 4 | 4 | 8 | 8 | 8 | 8 | 12 | 12 | 12 | 16 | 16 | 20 | 20 | ||

| ANSI B16.5 Class-300 | D b k d4 d2 z | 165 | 191 | 210 | 254 | 279 | 318 | 381 | 445 | 521 | 584 | 648 | |||

| 22 | 25 | 29 | 32 | 35 | 37 | 41 | 48 | 51 | 54 | 57 | |||||

| 127 | 149 | 168 | 200 | 235 | 270 | 330 | 387 | 451 | 514 | 572 | |||||

| 92 | 105 | 127 | 157 | 186 | 216 | 270 | 324 | 381 | 413 | 470 | |||||

| 19 | 22 | 22 | 22 | 22 | 22 | 25 | 29 | 32 | 32 | 35 | |||||

| 8 | 8 | 8 | 8 | 8 | 12 | 12 | 16 | 16 | 20 | 20 | |||||

- Testing as per API 598/BS : 5146

- Outside lever & Weight type can be provided.

- By Pass / Gear / Actuator can provide.

Superior Corrosion Resistance

With its advanced PTFE, FEP, or PFA lining, this swing check valve delivers excellent protection against highly corrosive fluids such as acids and alkalis, making it a trusted solution for challenging chemical and industrial environments.

Wide-Ranging Applications

Designed to meet the needs of industrial fluid handling and water treatment plants, the valve is suitable for various media including water, gases, and aggressive chemicalsthanks to its sturdy construction and versatile sealing options.

FAQs of Lined Swing Check Valve:

Q: How does a lined swing check valve function in industrial fluid handling?

A: A lined swing check valve allows fluid to flow in one direction and automatically prevents backflow. The swing disc swings open when fluid moves forward and closes when flow reverses, ensuring non-return operation. Its lining enhances resistance to corrosive and abrasive fluids typical in industrial settings.Q: What makes PTFE/FEP/PFA lining beneficial for corrosive chemical processes?

A: PTFE, FEP, and PFA linings offer exceptional chemical inertness, protecting the valve body from corrosive acids and alkalis. This ensures long service life, minimal maintenance, and safety when handling aggressive chemicals.Q: When should a PTFE or rubber-lined swing check valve be used over an unlined valve?

A: A PTFE or rubber-lined swing check valve is recommended when the fluid media contains corrosive chemicals, or when contamination must be avoided. Lined valves are preferred in applications such as chemical processing or water treatment where fluid purity and equipment longevity are critical.Q: Where are lined swing check valves commonly installed?

A: Lined swing check valves are commonly installed in pipelines of chemical industries, water treatment plants, and any facility managing corrosive or hazardous fluids. Their flanged ends and standard-compliant design allow integration with ANSI B16.5 or DIN pipeline systems.Q: What is the process for selecting the appropriate valve size and connection type?

A: Selecting the correct valve size and connection involves matching the valves DN (diameter nominal) size range, available from DN25 to DN300, to the flow requirements and pipeline diameter. The connection type, typically flanged ends per ANSI B16.5 or DIN standards, should correspond with existing system specifications.Q: How do users benefit from stainless steel pins and encapsulated discs?

A: Stainless steel pins provide durable hinge action and corrosion resistance, while metal-encapsulated or PTFE-lined discs offer reliable performance and extended service life, even in harsh media, ensuring consistent non-return operation and reduced maintenance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Swing Check Valve Category

Industrial Swing Check Valve

Price Range 700.00 - 7000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Port Size : DN25 to DN300 (1 to 12)

Control System : Manual

Media : Other, Water, Air, Oil, Gas, Steam

Type : Swing Check Valve

|

FLOMECH VALVES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry