Gate Valve Rising Spindle

MOQ : 1 Piece

Gate Valve Rising Spindle Specification

- Valve Size

- 50mm to 600mm (2 to 24)

- Material

- Cast Iron, Cast Steel, Stainless Steel, Ductile Iron, Carbon Steel

- Valve Type

- Rising Spindle Gate Valve

- Connection Type

- Flanged End

- Control System

- Handwheel operated

- Sealing

- Metal to Metal

- Application

- Industrial pipelines, water treatment plants, oil and gas, chemical and petrochemical industries, HVAC systems

- Structure

- Rising Spindle, Bolted Bonnet

- Type

- Gate Valve

- Power

- Manual

- Pressure

- PN16, PN25, Class 150, Class 300

- Media

- Water, Oil, Gas, Steam, Non Corrosive Liquids

- Port Size

- Full Bore

- Temperature

- Up to 450C

- Disc

- Solid Wedge

- Pin

- Steel

Gate Valve Rising Spindle Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- KOLKATA

- Supply Ability

- 10 Pieces Per Day

- Delivery Time

- 15 Days

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- AS PER ORDER

- Main Domestic Market

- All India

- Certifications

- ISO 9001:2015

About Gate Valve Rising Spindle

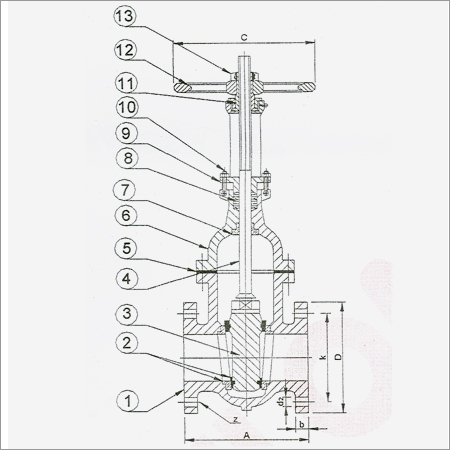

Gate Valve Rising Spindle

- Bolted Bonnet, Solid Wedge, Inside Screw & Yoke.

- Flange to Flange as per ANSI B16.10

- Flange Dimension as per ANSI B16.1

- Alternative Flanges can be provided.

| Body |

Cast Iron IS : 210 FG - 200 |

| Seat & Wedge Ring |

Stainless Steel AISI - 304 |

| Wedge |

Cast Iron IS : 210 FG - 200 |

| Spindle |

Stainless Steel AISI - 410 |

| Gasket |

C.A.F / Rubber |

| Bonnet |

Cast Iron IS : 210 FG - 200 |

| Backseat Bush |

Stainless Steel CF - 8 |

| Packing |

Graphited Asbestos |

| Gland |

Cast Iron IS : 210 FG - 200 |

| Bolts & Nuts |

Carbon Steel |

| Yoke Sleeve |

Gun Metal / Carbon Steel |

| Handwheel |

Cast Iron IS : 210 FG - 200 |

| Wheel Nut |

Carbon Steel |

| Hydrostatic Test Pressure in Kg/Cm2 (PSI) |

||

| Class |

Shell |

Seat |

| 125 |

24 (342) |

16 (228) |

Dimensions Are In MM

| Mark |

Size |

50 |

65 |

80 |

100 |

125 |

150 |

200 |

250 |

300 |

350 |

400 |

450 |

500 |

600 |

| A B |

178 |

190 |

203 |

229 |

254 |

267 |

292 |

330 |

356 |

381 |

406 |

432 |

457 |

508 |

|

| 203 |

203 |

229 |

254 |

305 |

305 |

381 |

457 |

533 |

610 |

610 |

686 |

686 |

BG |

||

| ANSI B 16.1 Class-125 |

D b k d2 Z |

152 |

178 |

191 |

229 |

254 |

279 |

343 |

406 |

483 |

533 |

597 |

635 |

699 |

813 |

| 19 |

22 |

24 |

24 |

24 |

25 |

29 |

30 |

32 |

35 |

37 |

40 |

43 |

48 |

||

| 121 |

140 |

152 |

191 |

216 |

241 |

298 |

362 |

432 |

476 |

540 |

578 |

635 |

749 |

||

| 19 |

19 |

19 |

19 |

22 |

22 |

22 |

25 |

25 |

29 |

29 |

32 |

32 |

35 |

||

| 4 |

4 |

4 |

8 |

8 |

8 |

8 |

12 |

12 |

16 |

16 |

20 |

20 |

20 |

- Testing as Per BS : 5146

- BG indicates as BEVEL GEAR.

- Chain Wheel / Gear / Actuator can be provided.

- Shoes & Channel position indicator / Extn. rod with coupling / By Pass arrangement can be provided.

Reliable Flow Control for Critical Applications

The Rising Spindle Gate Valve is designed for high-integrity flow isolation in industrial pipelines and utility networks. Its robust construction and solid wedge design provide dependable shut-off, making it ideal for systems where precise control over water, steam, oil, or gas is crucial. With a rising spindle mechanism, users can easily ascertain valve position, enhancing operational safety and maintenance efficiency.

Engineered to Withstand High Temperatures and Pressure

This gate valve is built to handle pressures up to Class 300 and temperatures reaching 450C. Its materials including stainless steel, cast iron, and carbon steel ensure exceptional resistance to thermal and mechanical stress. The metal-to-metal sealing system provides lasting durability and minimizes leakage, even under varying load conditions.

FAQs of Gate Valve Rising Spindle:

Q: How does the rising spindle mechanism benefit the operation of this gate valve?

A: The rising spindle design allows operators to visually determine the valves open or closed status by observing the stem position. This clear indication enhances process safety and makes manual control more intuitive, reducing the risk of incorrect operation in critical industrial environments.Q: What types of media can this gate valve safely handle?

A: This valve is suitable for a wide range of media, including water, oil, gas, steam, and non-corrosive liquids. Its robust construction and metal-to-metal seal ensure compatibility with demanding industrial fluids across various sectors such as oil & gas, power plants, and chemical processing.Q: Where is this rising spindle gate valve ideally installed?

A: It is designed for installation in industrial pipelines found in water treatment plants, HVAC systems, oil and gas fields, chemical plants, and petrochemical industries. Its full bore and flanged end connections make it suitable for both new systems and replacement projects in high-demand environments.Q: What materials are used in manufacturing these gate valves?

A: These valves are made from high-grade materials like cast iron, ductile iron, stainless steel, carbon steel, and cast steel. The material selection ensures strength, corrosion resistance, and durability in diverse operating conditions.Q: When should you choose a gate valve with a solid wedge disc?

A: A gate valve with a solid wedge disc should be selected when consistent, leak-tight shut-off is required, especially under changing pressures and temperatures. The solid wedge design is less susceptible to deformation, making it preferable for challenging industrial processes.Q: What is the typical process for operating and maintaining this valve?

A: Operation is manual, using a handwheel to raise or lower the spindle and open or close the gate. Routine maintenance includes checking the spindle for smooth movement and inspecting the sealing surfaces for wear, ensuring reliable long-term performance.Q: What are the main benefits of using a full bore, rising spindle gate valve?

A: The full bore design reduces flow resistance, minimizing pressure drop and energy loss across the valve. Combined with the rising spindle feature, it provides easy operation, visual status of the valve, and reliable shut-off, making it highly efficient for industrial fluid control.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Knife Gate Valve Category

Knife Edge Gate Valve

Price 700.00 INR / Piece

Minimum Order Quantity : 1 Piece

Valve Size : 2 to 24

Type : Knife Edge Gate Valve

Application : Slurry, pulp, powder and other media isolation in pipelines

Power : Other, Manual, Pneumatic, Electric

|

FLOMECH VALVES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry