Flap Type Check Valve

Flap Type Check Valve Specification

- Connection Type

- Flanged End

- Valve Type

- Check Valve

- Material

- Cast Iron, Ductile Iron, Stainless Steel (as per design)

- Sealing

- Resilient Seated/Soft Seat

- Application

- Flow control in water supply, wastewater, irrigation, and industrial fluid pipelines

- Structure

- Flap Type Body with Hinged Disc

- Type

- Swing Type Flap Check Valve

- Pressure

- PN10, PN16 (Customized on request)

- Port Size

- 50mm to 600mm (2 to 24)

- Disc

- Ductile Iron / Cast Iron / Rubber Coated

- Pin

- Single Hinge Pin

- Operating Principle

- Automatic closure by reverse flow

- Gasket Material

- EPDM/NBR Rubber

- Leakage Rate

- Zero leakage (soft seated standard)

- Installation Orientation

- Horizontal or Vertical (flow upwards)

- Face-to-Face Standard

- As per EN 558 / ISO 5752 / DIN 3202

- Application Area

- Water Treatment Plants, Sewage Systems, Pumping Stations

- Body Coating

- Fusion bonded epoxy or powder coated

- Max Working Pressure

- 16 Bar (PN16)

Flap Type Check Valve Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 1 Piece Per Day

- Delivery Time

- 15 Days

About Flap Type Check Valve

Established in the year 1992, we provide our precious clients an extensive range of Flap Type Check Valve. This valve is best suitable to fit with water pipe lines for controlling pressure of water. Offered valve finds its applications in swimming pools, storage tanks, and many more. The offered valve is manufactured by our diligent experts using quality approved raw materials and advanced techniques. Available in numerous models and other specifications, clients can purchase this Flap Type Check Valve from us at industry leading prices.

Features:

-

High strength

-

Application specific structure

-

Withstand high pressure

-

Rust resistance

| Product Specification | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

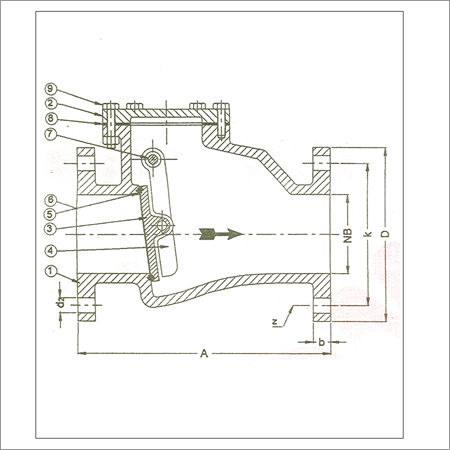

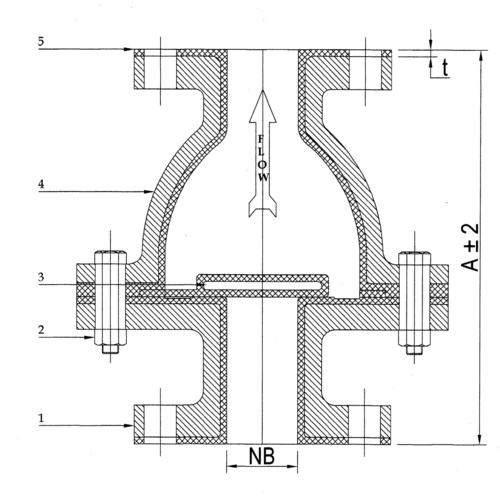

| FLAP TYPE CHECK VALVES Soft Rubber Moulded Carbon Steel Disc. Valves Body Lined With Natural / Synthetic / Hard Rubber. Flanges are as per IS: 1538, Table-4 & 6. Alternate Flange also available.

Materials Of Construction:

DIMENSIONS ARE IN MM

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Superior Backflow Prevention

Employing a resilient soft-seated design, this flap type check valve ensures zero leakage even under high pressures. The automatic closure mechanism is activated by reverse flow, providing reliable, maintenance-friendly protection in critical water, sewage, and fluid transport applications.

Durable Construction and Coating

Each valve body undergoes fusion bonded epoxy or powder coating, guarding against corrosion and extending service lifeideal for harsh operating conditions. Multiple body materials, including cast iron and ductile iron, allow for tailored performance based on system demands.

Versatile Installation & Operation

Designed to fit easily into new and existing pipelines, the flap check valves flanged ends and compliance with EN 558, ISO 5752, and DIN 3202 face-to-face standards ensure compatibility. Its vertical and horizontal installation flexibility meets a range of pipeline configuration needs.

FAQs of Flap Type Check Valve:

Q: How does the flap type check valve prevent water backflow in pipelines?

A: The valve automatically closes its flap (hinged disc) when reverse flow is detected, preventing water or wastewater from flowing back into the system. This automatic mechanism ensures secure one-way flow and dependable backflow prevention.Q: What are the primary benefits of using a soft-seated, resilient sealing check valve?

A: Soft-seated valves offer zero leakage, minimizing water loss and potential contamination. This resilience also ensures tight sealing, reduces maintenance frequency, and extends service lifeespecially in water treatment or sewage applications.Q: Where can this check valve be installed, and what are its suitable orientation options?

A: The flap type check valve is suitable for installation in water treatment plants, sewage systems, pumping stations, irrigation networks, and industrial fluid pipelines. It can be installed in both horizontal pipelines and vertical pipelines with upward flow, providing versatile system compatibility.Q: What materials and coatings are available for the valve body and disc?

A: Valve bodies are crafted from cast iron, ductile iron, or stainless steel, depending on system requirements. Protective coatings such as fusion bonded epoxy or powder coating are applied for enhanced resistance to corrosion and abrasion, increasing overall longevity.Q: When should an operator choose a flap type check valve with a soft seat design?

A: Operators should opt for a soft-seated flap check valve when zero leakage is crucialsuch as in potable water supply, wastewater management, or irrigation systemswhere fluid integrity and environmental safety are essential.Q: What gasket materials are used, and why are they important?

A: Gaskets are typically made from EPDM or NBR rubber, both known for chemical resistance and durability. The right gasket ensures a reliable seal even under varying pressures and fluid types, supporting consistent, leak-free operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Check / Reflux Valves Category

Reflux Valve

Price Range 10000.00 - 70000.00 INR / Piece

Minimum Order Quantity : 1 , , Piece

Structure : Other, Single plate, unibody construction

Application : Industrial fluid handling, chemical processing, water systems

Media : Other, Water, Oil, Gas

Industrial Check Valves

Minimum Order Quantity : 1 Piece

Structure : Check

Application : Industrial

Media : Water

|

FLOMECH VALVES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry