Knife Edge Gate Valve

Price 700.00 INR/ Piece

MOQ : 1 Piece

Knife Edge Gate Valve Specification

- Control System

- Manual Handwheel, Pneumatic Cylinder, Electric Actuator

- Material

- Cast Iron / Stainless Steel / Ductile Iron / Alloy Steel

- Connection Type

- Flanged / Wafer

- Valve Type

- Gate

- Valve Size

- 2 to 24

- Sealing

- Resilient or Metal Seated

- Application

- Slurry, pulp, powder and other media isolation in pipelines

- Structure

- Knife Edge Gate

- Voltage

- 24V, 110V, 230V, 380V AC (for actuated types)

- Type

- Knife Edge Gate Valve

- Power

- Manual, Pneumatic, Electric

- Pressure

- Class 150 / PN10

- Port Size

- DN50 to DN600

- Disc

- Stainless Steel / Cast Iron

Knife Edge Gate Valve Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10 Pieces Per Day

- Delivery Time

- 15 Days

About Knife Edge Gate Valve

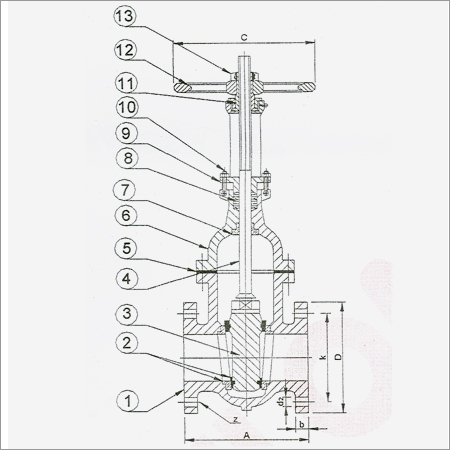

Gate Valve Non Rising Spindle

- Bolted Bonnet, Solid Wedge, Outside Screw & Yoke.

- Flange to Flange as per ANSI B16.10

- Flange Dimension as per ANSI B16.1

- Alternative Flanges can be provided.

| Body |

Cast Iron IS : 210 FG-200 |

| Dome |

|

| Cover |

|

| Gland |

|

| Wedge |

High Tensile Brass / S.S. - AISI 410 |

| Spindle |

Gun Metal / S.S. - CF - 8 |

| Seat & Wedge Ring |

Gun Metal / S.S. - CF-8 |

| Handwheel |

Cast Iron IS : 210 FG - 200 |

| Packing |

Graphited Asbestos |

| Bolts & Nuts | Carbon Steel |

| Gasket |

C.A.F |

| Cap |

Cast Iron IS : 210 FG - 200 |

| Hydrostatic Test Pressure in Kg/Cm2 (PSI) |

||

| Class |

Shell |

Seat |

| 125 |

24 (342) |

16 (228) |

Dimensions Are In MM

| Mark |

Size |

50 |

65 |

80 |

100 |

125 |

150 |

200 |

250 |

300 |

350 |

400 |

450 |

500 |

600 |

| A B |

178 |

190 |

203 |

229 |

254 |

267 |

292 |

330 |

356 |

381 |

406 |

432 |

457 |

508 |

|

| 203 |

203 |

229 |

254 |

305 |

305 |

381 |

457 |

533 |

610 |

610 |

686 |

686 |

BG |

||

| ANSI B 16.1 Class-125 |

D b k d2 Z |

152 |

178 |

191 |

229 |

254 |

279 |

343 |

406 |

483 |

533 |

597 |

635 |

699 |

813 |

| 19 |

22 |

24 |

24 |

24 |

25 |

29 |

30 |

32 |

35 |

37 |

40 |

43 |

48 |

||

| 121 |

140 |

152 |

191 |

216 |

241 |

298 |

362 |

432 |

476 |

540 |

578 |

635 |

749 |

||

| 19 |

19 |

19 |

19 |

22 |

22 |

22 |

25 |

25 |

29 |

29 |

32 |

32 |

35 |

||

| 4 |

4 |

4 |

8 |

8 |

8 |

8 |

12 |

12 |

16 |

16 |

20 |

20 |

20 |

- Testing as Per BS : 5146

- BG indicates as BEVEL GEAR.

- Chain Wheel / Gear / Actuator can be provided.

- Shoes & Channel position indicator / Extn. rod with coupling / By Pass arrangement can be provided.

Optimal Performance in Demanding Media

Knife Edge Gate Valves excel in isolating abrasive media such as slurry, pulp, and powders, where conventional valves may encounter operational difficulties. Their uniquely sharpened gate design allows them to cut through viscous or solid-laden flow streams, minimizing clogging and ensuring seamless pipeline operation. They are essential for industries such as mining, paper, chemical, and wastewater, providing dependable sealing and uninterrupted performance.

Flexible Control and Operation

Available with manual handwheel, pneumatic cylinder, or electric actuator control, these valves offer customizable operation suitable for a variety of process requirements. Actuated types can be powered at 24V, 110V, 230V, or 380V AC, accommodating available plant infrastructure. This flexibility enables integration with automated process control systems, improving safety, efficiency, and response times in critical pipelines.

FAQs of Knife Edge Gate Valve:

Q: How are Knife Edge Gate Valves used in slurry and pulp pipeline applications?

A: Knife Edge Gate Valves are specially designed to cut through and isolate slurries, pulps, and other thick or particulate-laden media. Their sharpened gate travels through the medium, preventing buildup and allowing for a tight shutoff that minimizes leakage and maintenance requirements.Q: What are the main benefits of choosing a knife edge gate valve for powder isolation?

A: These valves are highly effective for handling and isolating powders due to their ability to prevent clogging and ensure tight closure. Their robust construction and precision gate design reduce downtime and enhance process reliability in powder conveying systems.Q: When should I use a manual, pneumatic, or electric actuator for my valve?

A: Manual actuation is ideal for simple or infrequent operations. Pneumatic actuators suit applications requiring quick, remote, or repetitive operation with compressed air access. Electric actuators are preferred for automated processes needing precise control and integration with plant systems, especially where electricity is readily available.Q: Where are knife edge gate valves commonly installed?

A: These valves are widely used in industries such as mining, paper and pulp, chemical plants, and wastewater treatment facilitiesessentially anywhere reliable isolation of abrasive, dense, or particulate media in pipelines is required.Q: What is the process for selecting the right size and material for a knife edge gate valve?

A: Selection depends on the nature of the media, pipeline size (DN50DN600 / 224), pressure rating (Class 150 / PN10), and required durability. Materials like cast iron, stainless steel, ductile iron, or alloy steel are chosen based on media compatibility, corrosion resistance, and operational conditions.Q: How does the sealing type (resilient or metal seated) impact the valves performance?

A: Resilient seats provide bubble-tight shutoff and are ideal for lighter slurries and powders, while metal seats offer greater durability and resistance to abrasion or high temperatures, making them suitable for harsh or abrasive environments.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Knife Gate Valve Category

Gate Valve Rising Spindle

Price Range 700.00 - 7000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Cast Iron, Cast Steel, Stainless Steel, Ductile Iron, Carbon Steel

Connection Type : Flanged End

Type : Gate Valve

Media : Other, Water, Oil, Gas, Steam, Non Corrosive Liquids

|

FLOMECH VALVES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry